A Better Process For Bases And Plates

In a mold shop, the model of the customer's part gets used in two parallel processes. One of these is core and cavity machining, in which CAM software generates complex tool paths to let CNC machining cut the shape of the part in metal.

Share

In a mold shop, the model of the customer’s part gets used in two parallel processes. One of these is core and cavity machining, in which CAM software generates complex tool paths to let CNC machining cut the shape of the part in metal.

The other process is base and plate machining. Here, the work is less likely to flow so smoothly. Mold design software may be used to model the bases and plates based on the core/cavity geometry, but the automation usually ends after that. If a model is imported into CAM software, a programmer likely will spend time selecting tools and machining operations for each individual feature. If the component is machined manually—as when a plate model is converted to a hole location chart—then the toolmaker performs this same selection but machines each feature as he goes. Either way, these components require mental labor and therefore impose a delay. This can seem ironic, given that the core and cavity are the components with the complex geometry.

But look closer, and the irony disappears. Cores and cavities are complex only in terms of geometry. Plates and bases are complex in a different way. While the tool paths to machine a plate may be simple indeed—just a series of hole-making plunges—the complexity comes in choosing the tools and operations. A plate with 100 or more holes might require dozens of center drills, drills, chamfers and taps in various combinations. Some holes will also call for a choice between drilling and helical milling.

In other words, the complexity of a plate lies in the knowledge necessary to machine it.

That’s why software to automate plate production needs to be knowledge-based.

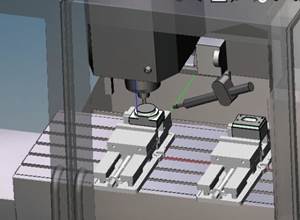

An example of such software comes from Cornerstone Technology. The company’s newly introduced “Expert Mold Maker” recognizes the holes and pockets of bases and plates and automatically generates programs to machine these components based on rules the user can change.

Based in Windsor, Ontario, Cornerstone is best known to mold makers in the Detroit area. The knowledge-based software builds on an existing product called Expert Mold Designer, used chiefly among automotive mold makers to automate base and plate modeling. Where the existing software is strictly CAD, the new software sees the process through to postprocessed NC code.

To achieve the automatic programming, Cornerstone partnered with Pathtrace (Southfield, Michigan). Pathtrace incorporates feature recognition and knowledge-based machining into its own product, EdgeCAM. Similar algorithms allow the mold software to generate code from base and plate designs and allow users to revise the rules governing how various features are machined.

Most shops probably will change these rules. The shop that prefers to helical mill a class of hole that would usually be drilled, for example, can adjust the rules accordingly. In this way, the software captures a shop’s preferences and expertise.

Thus the software delivers several benefits. Chief among these are speed and precision. Programs are generated without delay and without the kind of error that can result from misreading a number on a hole chart.

But another benefit is the reduced dependence on skilled personnel. In a typical shop, how well or how quickly a plate is machined depends on which employee has that job. The knowledge-based software changes that. It also lets the shop worry less about the prospect that a skilled toolmaker might retire or might leave the shop and take his knowledge away.

Related Content

TTI Brings Specialty Gear Production In-House with Multiaxis Machining

By investing in a 3+2-axis machine and utilizing simulation software for diagnostic checks, Techtronic Industries turned a four- to ten-week lead time into a one- to two-week lead time.

Read MoreBuilding A Powerful Bridge from the CAM Programmer to the Shop Floor Operator

SolidCAM for Operators provides a powerful bridge from CAM programming to the shop floor to best streamline the machine shop process with its CAM part simulation. It provides a clear picture to the operator for setup and prove-out, enables minor G-Code changes and avoids crashes, broken tools and scrapped parts.

Read MoreHow Integrated CAD/CAM Transforms Inventions Into Products

The close connection between CAD and CAM is what links creative ideas to practical production for this unique custom manufacturer.

Read MoreLarge-Format Machining With Small Cutting Tools and Dynamic Motion

Napoleon Machine, a defense contractor that provides parts for the M1 Abrams tank, recently took advantage of a CAM feature that allowed the company to streamline its cutting strategies and program offline. Here’s how the shop cut cycle times nearly in half with its large-format five-axis machining operations.

Read MoreRead Next

Machine Shop MBA

Making Chips and Modern Machine Shop are teaming up for a new podcast series called Machine Shop MBA—designed to help manufacturers measure their success against the industry’s best. Through the lens of the Top Shops benchmarking program, the series explores the KPIs that set high-performing shops apart, from machine utilization and first-pass yield to employee engagement and revenue per employee.

Read MoreAMRs Are Moving Into Manufacturing: 4 Considerations for Implementation

AMRs can provide a flexible, easy-to-use automation platform so long as manufacturers choose a suitable task and prepare their facilities.

Read More