A Modular Clamping System for Bulky Parts

Here’s one fixturing alternative for clamping large workpieces such as mold and fracking components.

Share

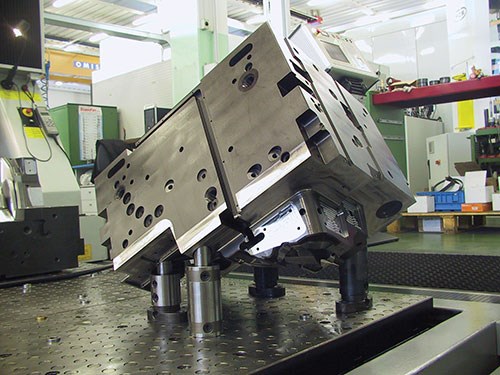

The FCS modular clamping system was designed to minimize setup times, enable machines to access five sides of a fixtured part and provide highly repeatable positioning so parts can be removed and accurately refixtured as needed.

FCS Moulds, now Elmann S.R.L.U., is an Italian moldmaker that sought to develop a standard means of fixturing mold components that would minimize setup times, enable its machines to access five sides of a fixtured part, and provide highly repeatable positioning so parts could be removed and accurately refixtured at the same zero reference points as needed. Ultimately, its goal was to increase its machines’ spindle utilization so it could be more competitive with foreign moldmakers.

The solution it developed eventually turned into a product line that’s well-suited for clamping big, bulky components. Learn how you might benefit from it.

Related Content

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

Medical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.