Consolidated Clamping Assembly Made by Additive Manufacturing

Metal additive manufacturing made it possible to condense a three-part clamping assembly into a single piece.

Share

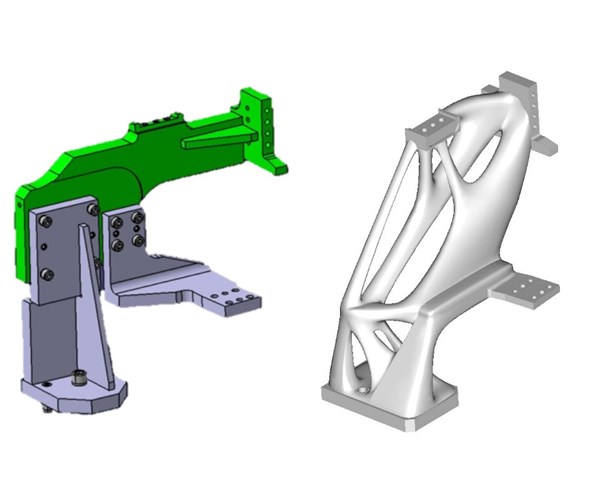

This clamping unit used in Comau welding and assembly operations was redesigned for additive manufacturing, enabling the three-part assembly (left) to become just one piece (right).

Redesigning a part with additive manufacturing in mind often means simplifying or even eliminating fabrication by combining an assembly into fewer complex components. In a recent application, industrial automation supplier Comau used selective laser sintering (SLS), a powder-bed additive technology, to create in one piece a clamping assembly that had previously been made from multiple distinct parts.

This clamping assembly (pictured above) is used to secure parts of Comau equipment for welding and assembly. The original clamping unit was made in three parts from steel S355JR. The additive-manufactured version was selective laser sintered in just one piece out of ALSi10Mg, resulting in a stronger and lighter component. Light postprocessing was performed on the fitting areas and holes, but no other finishing work was required.

Read more about the redesign and benefits of this additively manufactured clamping assembly from sister publication Additive Manufacturing.

Related Content

-

Digital Thread Enables First-Time-Right 3D Printing

Connecting all stages of manufacturing, from design to postprocessing, helps break down barriers to industrializing additive manufacturing.

-

Designing a 3D Printed Part with Machining in Mind

Designing extra stock and mounting features into a 3D printed part can aid in machining processes downstream.

-

Digitalization and Done-In-One Reign Supreme at BIEMH 2024

European manufacturers may have a different balance of markets than their U.S. counterparts, but the practical challenges they must overcome are often similar — as are the solutions.

.jpg;width=70;height=70;mode=crop)