Features for More Flexible Measurement

To support a variety of applications, materials and workpiece sizes, measurement and inspection equipment suppliers are offering features such as automated measuring and multiple sensors.

Share

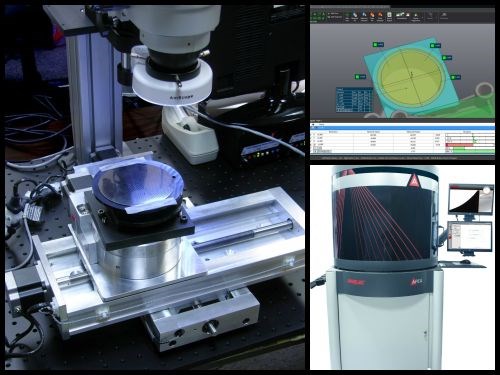

While measurement and inspection are necessary parts of the manufacturing process, the right equipment and features can help reduce the time and operator involvement required and limit the number of machines and steps. Fully automated systems such as Parlec’s Apex profile measuring machine and those with one-touch measurement like the Mitutoyo Quick Image 2D optical measuring machine can speed this step while reducing operator error. Other systems emphasize flexibility and diverse capability, such as the Zeiss O-Inspect which can be equipped with three different sensors to accommodate a range of workpiece sizes.

Click the image above for a slideshow featuring these and other measurement and inspection products.

Related Content

-

Parts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

-

Measuring Torque, Thrust Force for Smart Drilling Operations

To monitor drilling operations for smart manufacturing solutions, torque and thrust force can be measured.

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

.jpg;width=70;height=70;mode=crop)