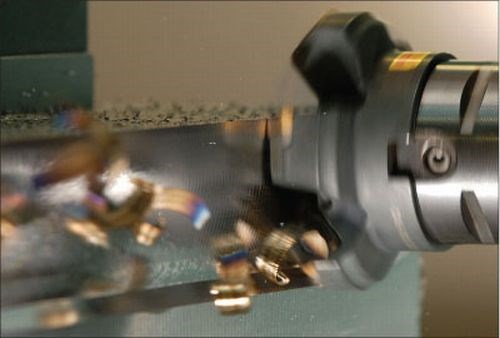

Milling HRSAs: The Checklist

When milling super alloys, there are certain process requirements that must be observed.

Share

The article is part of the Milling Aerospace Alloys area of Sandvik’s new online knowledge center devoted to Titanium & HRSA Machining. If you are struggling to obtain more productivity in any of these high-temperature aerospace metals, take a moment to click through the resources that Sandvik Coromant has gathered together here.

Related Content

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

Shoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

-

Quick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.