Simulating Automation

Software designed for simulating and controlling machine-tending robots can help avoid collisions, protect equipment and simplify the setup of automated cells.

Share

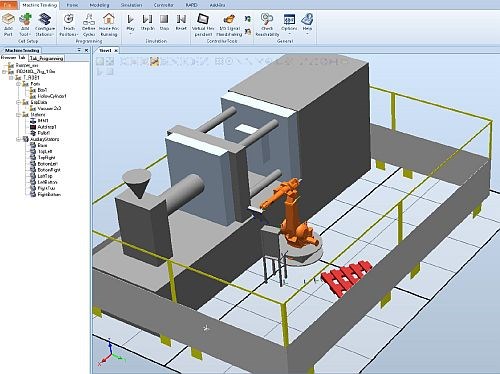

ABB’s RobotStudio software enables the offline programming of robots.

When equipped with the Machine Tending PowerPac add-on, the system can simulate the complete tending cycle of a robotic cell.

Robotic cell automation has the potential to improve machine utilization, reduce costs, even increase worker safety—but only if the robots are set up and functioning properly. has developed an add-on for its PC-based RobotStudio software that enables users to check the operation of a robotic cell before costly mistakes are made on the shop floor.

The add-on is designed to help get a robotic cell up and running safely. The program includes a vast library of grippers and station types along with support for most machines and peripheral equipment. This data enables the system to realistically simulate, validate and optimize a robotic cell in the 3D virtual world before the system is put to work, even before the components are physically installed if necessary. According to the company, everything from cycle times to collision risks can be visualized through the software, improving productivity and preventing crashes.

Visit ABB’s website to learn more about its .

Related Content

-

5 Stages of a Closed-Loop CNC Machining Cell

Controlling variability in a closed-loop manufacturing process requires inspection data collected before, during and immediately after machining — and a means to act on that data in real time. Here’s one system that accomplishes this.

-

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

-

Medical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

.jpg;width=70;height=70;mode=crop)