With 3D Printing, Fixture Making Goes from the Tool Room to the CAD Room

For Ira Green Inc., fixture design and iteration used to take days, even weeks at times, and at a high cost per fixture. With a 3D printer, the shop’s entire process has changed, drastically increasing efficiency and cost effectiveness.

Share

Founded in 1943, (IGI), headquartered in Providence, Rhode Island, is a full-service manufacturer and distributor of nearly 40,000 different accoutrements for military uniforms. IGI’s tool shop is focused, therefore, on manufacturing coining and blanking dies. It also produces small fixtures for welding and polishing.

With high demand for IGI products, new fixtures are required every day. However, each job had to wait in a queue for several days before it could begin, resulting in bottlenecks. Lead times between job requests and fixture delivery ranged from several days to weeks. Moreover, each fixture required eight hours of CNC programming, either for setup of pockets or contour electrodes for tool steel and wire EDM flat pockets. IGI was spending $300 for every fixture.

Welcome! You鈥檝e unlocked premium content.

IGI’s manufacturing manager Bill Yehle argued that creating fixturing from 3D-printed plastic components instead of asking toolroom personnel to machine metal fixturing components would reduce the toolroom backlog while maintaining headcount. He proposed that using a 3D printer from Rize Inc. to print fixture parts would enable IGI to move that work to the fast-response CAD group instead of the overburdened toolroom.

“Implementing Rize 3D printing as part of a strategic process shift has completely transformed our production process,” Mr. Yehle says. In short, the shift has added toolroom skills to higher-skilled CAM and machine building tasks, so that fixture design can be accomplished at the time of product design, following the design/manufacturing development process along a parallel path.

From $300 per Fixture to $2

Prior to using Rize, machine operators clamped the piece down on the machine, which required considerable trial and error to get the placement right. They also tried melting the mold into nylon to hold it in place, but this also required a time-consuming process of trial and error—“turning and burning,” as Mr. Yehle calls it—and did not meet IGI’s accuracy requirements.

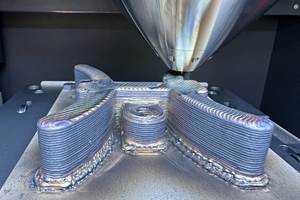

Precision is critical. The 3D-printed fixtures hold the piece while it is being nailed in the welder and ensure the precision and accuracy of the nail placement. This speeds the process because it eliminates the need for repeated manual adjustment of the fixtures. It also saves time from machine operators placing one nail at a time using traditional machining. Using fixtures printed with the Rize One machine, IGI has been able to standardize the center of the fixture for nailing the piece without requiring adjustment.

Since implementing 3D printing less than a year ago, IGI’s design team has printed approximately 300 fixtures. It now uses the Rize One 3D printer every day to reliably manufacture fixtures in 50 minutes at a cost of $2 per part. This enables IGI’s design team to produce seven different versions of fixtures per day that can be used for welding and polishing. Using the Rize One, IGI is able to standardize the molds and the nails, resulting in faster setup and change-over, repeatability, and increased accuracy. Mr. Yehle says the shop has realized an 80 percent time savings in setup and change-over times and has virtually eliminated errors.

Besides speed and accuracy in making fixtures, IGI’s designers have found use in the Rise One’s ink marking capability. They use it to print work order numbers, line numbers and pictures of the piece on the fixtures for identification as well as instructions for part use and storage. These markings also serve as three points of verification for machine operators to prevent errors.

When IGI has to fabricate steel fixtures to sustain heavier workpiece loads, staff still use the 3D printer for functional prototypes. The designers iterate the prototypes until they get them right and then turn to the toolroom for final steel fixture manufacturing. Previously, the shop iterated fixture designs two or three times in steel at a cost of $300 and lead times of two days per iteration. Rize enables IGI to produce seven prototypes per day at $2 each.

3D Printing on the Radar

IGI had been thinking about implementing 3D printing to improve its processes for some time before implementing the Rize One, which it chose after seeing it demonstrated at an event and in consultation with Rize and authorized reseller Caelynx. IGI was impressed with the part strength and industrial material properties Rize was able to work with, which enable fixtures to be drilled, polished and welded without welding flash and without increasing part temperature during welding.

Equally important to IGI’s strategy of operating 3D printers in its design office is that Rize 3D printers are easy enough to use that the existing design staff could operate them. IGI’s industrial designer, who had not used a 3D printer since he was a college student, said he was able to get up and running with Rize One quickly and easily.

IGI continually develops its use of the Rize One for fabricating fixtures. The company regularly iterates its fixtures for easier removal of the molds from nail and welding machines and to further enhance the standardization and repeatability of the production process.

Some of these enhancements include printing fixtures within fixtures. In this situation, the base fixture is a standard size while the fixture insert is customized for the workpiece, threading the molds for screws and printing spacers that enable selected molds to fit securely on certain machines.

IGI is also considering using the 3D printer to manufacture service and spare parts on demand for its machinery in order to reduce the time and cost of sourcing and ordering machined parts, especially when parts are obsolete or suppliers go out of business.

Related Content

JTEKT Technology Days Showcases Synergies

The event took place following the company’s completion of its new showroom and decision to merge several of its brands under the JTEKT name.

Read MoreAdditive/Subtractive Hybrid CNC Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MorePush-Button DED System Aims for Machine Shop Workflow in Metal Additive Manufacturing

Meltio M600 metal 3D printer employs probing, quick-change workholding and wire material stock to permit production in coordination with CNC machines.

Read MoreChuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MoreRead Next

Hype continues to surround additive manufacturing. These three factors can help determine whether a part is worth 3D printing.

A New Frontier in Surface Finish Control

What if your machine tool could measure surface roughness as it cuts? This article explores how in-process metrology is advancing from concept to reality, enabling real-time feedback, immediate detection of anomalies and new levels of control over surface quality. Discover the technologies making this possible.

Read MoreHow I Made It: Dennis Rymanowski

Dennis Rymanowski has worked at NSH USA for 60 years, with his passion for manufacturing living alongside his passion for his family’s polka band.

Read More