Evan Doran Senior Associate Editor

Generative Design for Milling Lightweights EV Motorbike Part

Autodesk’s Fusion 360 generative design function can create mass-saving solutions for three-axis milling and other conventional manufacturing processes.

Read MoreBio-Based Machining Fluids Improve Efficiency and Tool Life

New bio-based machining fluid formulations improve tool life and productivity without troublesome films and foams.

Read MoreZero-Adjustment Bar Pullers Simplify Turning Automation

Spring-loaded grippers and adjustable programming are enabling bar pullers to fulfill their promise to save time and money in CNC turning automation.

Read MoreCAM Automation and Library Revitalize Precision Manufacturer

CAMWorks has powered TECMA’s transition to 3D digital CNC machining. The software’s optimizations have enabled the shop to tackle precision parts for space.

Read MoreMethods and Benefits of Designing for Additive Manufacturing

Additive manufacturing may have different process considerations than traditional manufacturing, but it can manage these through clever planning and specialized software.

Read MoreNew CAD/CAM Features Extend Shop's Three-Axis Capabilities

Mastercam’s Dynamic Motion technology enables advanced tool paths that make Industrial Machine & Supply competitive with only a three-axis milling machine.

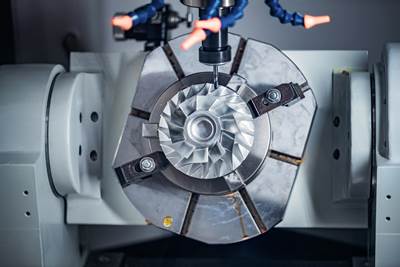

Read MoreWhy Go Five-Axis: Machine Types and Benefits

Even as the benefits of five-axis machining stack up year by year, the barrier for entry crumbles.

Read MoreFusion 360 Leaps Into the Cloud with Extensions and Forge

At its Autodesk University 2021 conference, Autodesk announced upcoming features for Fusion 360 such as generative design updates and integration with the company’s cloud-based Forge platform.

Read MoreEnd Mill and Collet Combo Cuts High-Speed Machining Costs 62%

Switching to Emuge-Franken helped precision production machine shop SB Dezigns save 62% in costs on a popular automotive part while lowering cycle times.

Read MorePutting Production on Repeat with Machine Tool Automation

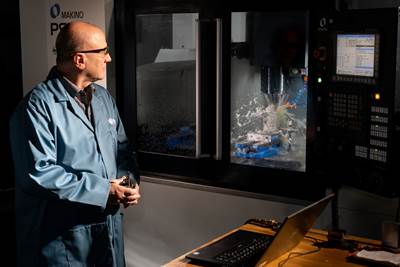

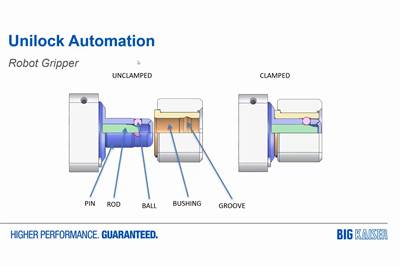

Cobots and automation advances have spurred tooling and workholding innovations like Big Daishowa’s zero-point workholding system and EWA fine boring head.

Read MoreSimulation Saves Money When Machining Expensive Parts

Jobs machining expensive materials mean Keselowski Advanced Manufacturing needs to be extremely cautious. The operations manager says Vericut not only prevents mistakes, it shortens cycle times.

Read MoreFour-Flute Carbide Drill Increases OWSI's Feedrate Fourfold

Ceratizit’s line of WTX-HFDS drills saved OWSI 3.5 minutes per part on a difficult job and completely eliminated a secondary operation, increasing profitability.

Read More