Agile's Machine Tending System Enables Lights Out Machining

Agile Robotics Systems has added compact models to its Agile Flex range of machine loaders, which are compatible with any CNC machine.

Share

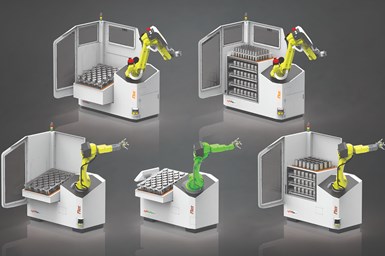

Agile Robotic Systems has introduced three new compact platforms to complement its existing heavy-duty models in the Agile Flex CNC range of machine loading systems.

Agile Flex is a range of out-of-the-box robotic loading systems for CNC machine tools. The company says these systems are rapid to deploy, compact, easy to use and enable lights-out machining on any CNC machine.

The existing models include the Agile Flex 35P (pallet), which is a system for heavy parts and large CNC machines, and the Agile Flex 35D (drawer), which is a multi-layer drawer system that is designed to increase overall capacity and unmanned run time.

The new models are compatible with smaller CNC machine tools and workpieces. The Agile Flex 12P and Agile Flex 12D models include all the features of the larger Agile Flex 35P and Agile Flex 35D models, including a software package that’s designed to be easy to use and requires no robot programming experience.

The Agile CoFlex 15P, featuring a FANUC CR-15iA collaborative robot, allows the operator and machine to work even closer together, removing requirements for safety scanners and barriers.

All three of the smaller models handle workpiece weights ranging to 9 lbs (double gripping) with a maximum diameter of 4" and length of 12". Agile says users can set up new parts in-house in minutes.

Related Content

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

-

5 Stages of a Closed-Loop CNC Machining Cell

Controlling variability in a closed-loop manufacturing process requires inspection data collected before, during and immediately after machining — and a means to act on that data in real time. Here’s one system that accomplishes this.

-

Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.