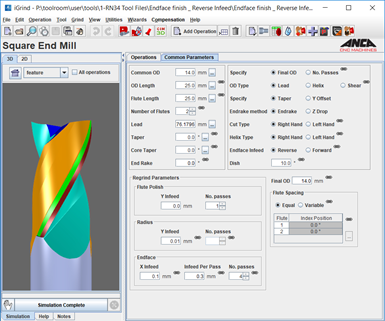

ANCA's ToolRoom RN34 Software Eases Design of Complex Helical Tools

ToolRoom RN34 is the latest generation of ANCA’s software package designed for making cutting tools.

Share

ToolRoom RN34 is the latest generation of ANCA’s software package designed for making cutting tools in the aerospace, die/mold, general machining and power generation industries.

According to Software Product Manager Thomson Mathew, the software enables users to design complex tool geometries for improved tool life, productivity and cutting volume. “The constant helix ballnose option, for example, is replaced by a graphical drag-and-drop designer,” he says. The software can switch from 2D projection of the cutting edge to 3D, easing the optimization of irregular helix curves to reduce vibration.

ToolRoom supports both manufacturing and regrinding applications.

Related Content

-

Bringing Machining In-House to Keep up With Demand for Offroading Parts

To meet demand increases for its Ford offroad industry components, supplier RPG Offroad brought its machining processes in-house, saving the company nearly $50,000 per month. Here’s how its choice of integrated CAD/CAM software made it happen.

-

Building A Powerful Bridge from the CAM Programmer to the Shop Floor Operator

SolidCAM for Operators provides a powerful bridge from CAM programming to the shop floor to best streamline the machine shop process with its CAM part simulation. It provides a clear picture to the operator for setup and prove-out, enables minor G-Code changes and avoids crashes, broken tools and scrapped parts.

-

Can ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.