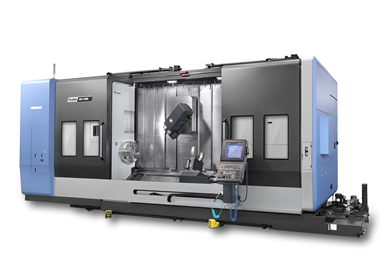

Doosan Puma SMX5100L Turn-Mill Has More Chuck Sizes

The Doosan Puma SMX5100L is a twin-spindle, multi-tasking turn-mill center designed to complete complex parts in a single setup, with chuck sizes available in 15, 18 and 21 inches.

Share

Doosan Machine Tools’ Puma SMX5100L is the latest addition to the company’s twin-spindle, multi-tasking turn-mill centers. The Puma SMX Series is specifically designed to complete complex parts in a single setup.

The Puma SMX5100L is the largest machine in the SMX Series, with a maximum turning diameter of 32.7" and maximum turn length of 120.1". Chuck sizes of 15", 18" and 21" are available for the standard main turning spindle, which features a 49.6-hp built-in motor that spins at 2,400 rpm. Also available is an optional gear box spindle that rotates at 1,500 rpm and outputs 4,198 Nm (3,096 foot-pounds) of torque for heavy duty applications.

A 49.6-hp motor rotating at 10,000 rpm powers the B-axis milling head, which features a Capto C8. The company says the roller gear cam mechanism that drives the B-axis is backlash-free and highly rigid, outputting B-axis torque of 2,700 Nm (1,991 foot-pounds).

According to the company, the machine is suitable for aerospace applications, including landing gear components, and housing for large shafts like those found in the agriculture and oil industries.

The Puma SMX machines are designed to have rigid machine construction. Strategically placed sensors throughout the machine offer real-time measurement and adjustment of the axes to minimize thermal deformation. For added stability and speed, three rows of cross-roller linear guideways support the Z-axis in which the carriage moves.

The Puma SMX line also comes standard with ergonomic features that improve operator convenience and efficient maintenance, including FANUC five-axis machining software offering 600 blocks of look-ahead and improved servo acceleration/deceleration.

Related Content

-

Multitasking Machines Cut Days From Shop’s Setups

Adopting WFL Millturn machines enabled BWXT to condense operations and setups while also providing a simple way to simulate and secure processes.

-

Swiss-Type Control Uses CNC Data to Improve Efficiency

Advanced controls for Swiss-type CNC lathes uses machine data to prevent tool collisions, saving setup time and scrap costs.

-

Machine Tool Drawbar Made With Additive Manufacturing Saves DMG MORI 90% Lead Time and 67% CO2 Emission

A new production process for the multimetal drawbar replaces an outsourced plating step with directed energy deposition, performing this DED along with roughing, finishing and grinding on a single machine.