Guided TA Tool Overcomes Cross-Hole Drilling Hurdles in Moldmaking

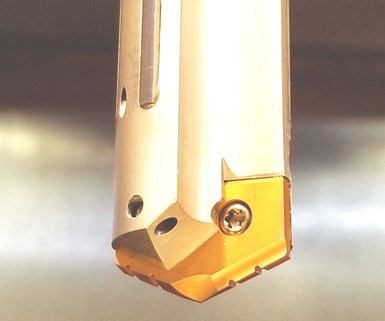

Allied Machine & Engineering’s Guided TA drill for moldmaking applications is used for producing water lines.

Share

Allied Machine & Engineering’s Guided TA drill for moldmaking applications is designed to overcome two primary hurdles associated with cutting waterlines in large molds: tool failure in deep cross holes, and chip evacuation. Intersecting channels often connect off-center or at non-perpendicular angles. The interrupted cuts can cause premature tool failure if cutting forces are imbalanced. In addition, deep holes can present issues with proper chip formation and removal.

To ensure stability, the Guided TA drill features minimal clearance between the holder and blade. It also incorporates guided wear pads for straightness and stability and two adjustable Torx Plus screw pins for total indicator runout reduction via simple diameter adjustment. These features are said to enable the tool to drill to an 84" depth of cut while producing balanced cutting forces and small chips for optimal evacuation.

Related Content

-

Parts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

-

Toolpath Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s toolpath can dramatically improve its ability to manage chips.

-

Briquetting Manufacturer Tools Up for Faster Turnaround Times

To cut out laborious manual processes like hand-grinding, this briquette manufacturer revamped its machining and cutting tool arsenal for faster production.