Mastercam 2021 Improves Safety, Speed of NC Programming

Mastercam 2021 increases machining productivity and reduces overall production costs with speed and flexibility improvements in multi-axis and turning applications.

Share

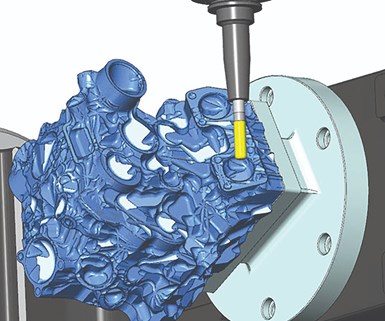

Mastercam 2021 offers speed and flexibility improvements in multi-axis and turning applications.

Expanded Multiaxis Pocketing combines efficient pocket cutting with a focus on finishing with Accelerated Finish tools, automatically maintaining the correct tool contact within defined parameters. The user can now analyze and modify the UV direction on surface models, expanding the power and flexibility of multi-axis flowline milling tool paths. The new 3+2 Automatic Roughing feature automatically makes multi-plane three-axis roughing tool paths by evaluating the model and stock, creating a cut, calculating what remains, and repeating the process until roughing is complete.

Mastercam 2021 features expanded support for modeling chucks and chuck jaws. Users can now define them by selecting a solid model. Mastercam Mill-Turn supports collet chucks as individual component types to expand the range of machines that can be directly supported. Mill-Turn Simulation has also been added to the Mastercam Simulator interface. Mastercam’s Swiss machining solutions combine Mastercam Mill and Mastercam Lathe with specialized postprocessors, adding machine-specific controls inside the Mastercam interface to deliver accurate G code for a variety of Swiss-type lathes.

Other improvements to Mastercam 2021 are said to contribute to fast, safe and precise NC programming. The Advanced Drill tool path is a customizable multi-segment drill cycle designed for spot drilling, deep-hole drilling and back spot facing, enabling each segment of the drill cycle to be defined and customized. When using tools with a tip angle, the Chamfer Drill tool path chamfers holes after calculating the correct depth based on the desired width or depth. It also enables users to select holes of different diameters or sizes, or holes that lie in different planes, and machine them in a single operation with a single tool.

Related Content

-

2 Secondary Coordinate Systems You Should Know

Coordinate systems tell a CNC machine where to position the cutting tool during the program’s execution for any purpose that requires the cutting tool to move.

-

ERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.

-

Can AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.