NCG CAM v17.0 Updates UI with Ribbon Design

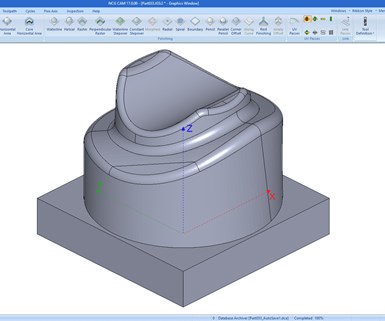

NCG CAM v17 features an updated user interface whose ribbon design organizes the program into a series of tabs at the top of a window.

Share

NCG CAM v17 features an updated user interface whose ribbon design organizes the program into a series of tabs at the top of a window. According to the company, the new ribbon layout will make it easier for the user to discover new features and functions.

Dynamic Material Removal has been added alongside the existing cutter animation function. It can indicate the direction of milling (climb or conventional) and identify any gouges or collisions. The feature is said to enable better visualization and verification of the material stock removal produced by the calculated tool path.

The software’s Drilling Hole Shape Database and Compound Drilling Cycles can create a searchable database of hole shapes. Several cycles can be grouped together as compound cycles to apply them to specific hole shapes. The Compound Drilling Cycle can also be applied to holes of different directions (tool axis) so that holes with different directions but the same hole shape can be programed in one step.

The Coordinate System module has been extended to include axis rotation information. The user can create a points folder containing key reference points and define the orientation. The module then repositions the imported part(s) or tool path(s) to the selected plan.

Another new feature enables the user to project a 2D boundary onto the surface. 3D curves can now be projected from a 2D boundary. This is mainly aimed at 3+2 five-axis machining, since existing boundaries are drawn above the surfaces along the tool axis, the company says.

Related Content

-

Can ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

-

The Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

-

TTI Brings Specialty Gear Production In-House with Multiaxis Machining

By investing in a 3+2-axis machine and utilizing simulation software for diagnostic checks, Techtronic Industries turned a four- to ten-week lead time into a one- to two-week lead time.