Renishaw's Free CARTO 4.2 Update Enhances XM-60

Renishaw’s CARTO 4.2 software suite provides new features for calibration equipment, notably extending the measurement range of the XM-60.

Share

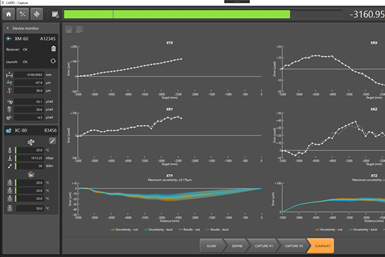

Renishaw’s CARTO 4.2 software suite for calibration products adds new features to the company’s XM-60 multi-axis calibrator and other calibration products.

First among the Renishaw XM-60’s new features in CARTO 4.2 is the ability to utilizes dynamic data fit functionality to quickly capture and analyze data from linear axes of any length. As the XM-60 provides direct measurement of all six degrees of freedom (linear, vertical and horizontal straightness, pitch, yaw and roll) on any form of linear axis, the company believes unlimited measurement range will be prove extremely useful.

The dynamic data fit functionality within the CARTO Capture application also recalculates test data in CARTO Capture to reduce outlying data-points. This improved method offers greater resilience to environmental interference and a better representation of straightness errors for longer axes.

Aside from the XM069, the CARTO Compensate 4.2 application now offers Heidenhain linear compensation, allowing laser users to apply pitch error compensation to Heidenhain machine tool controls in a simple process.

Renishaw says it plans to continually develop the CARTO software suite to add value for users of its calibration products. CARTO 4.2 is available to download free of charge at .

Related Content

-

Process Control — Leveraging Machine Shop Connectivity in Real Time

Renishaw Central, the company’s new end-to-end process control software, offers a new methodology for producing families of parts through actionable data.

-

The Many Ways of Measuring Thickness

While it may seem to be a straightforward check, there are many approaches to measuring thickness that are determined by the requirements of the part.

-

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.