Robotics Software Seamlessly Integrates With CAD/CAM

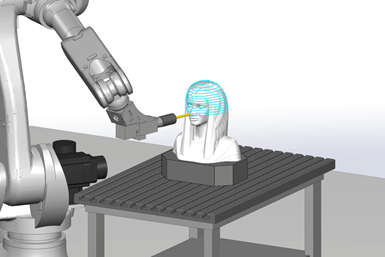

Robotmaster 2023 bridges the gap between CAD/CAM and robotics by enabling seamless integration between a user’s chosen CAD/CAM software and Robotmaster.

Share

, a U.S. based manufacturer of industrial cutting products and software, announces a major version update and new name for its Robotmaster offline programming software for robots: Robotmaster 2023.

Robotmaster 2023 is said to bridge the gap between CAD/CAM and robotics by enabling seamless integration between a user’s chosen CAD/CAM software and Robotmaster. This automatic integration eliminates the need to import and sync data for a 75% reduction in programming time. It also eliminates the programming errors that can happen when using a manual process, according to the company.

In addition, the new Robotmaster version enables for the creation of libraries that provide a more convenient way to store and re-use robotic cell components. Users can easily preview and select components within the library and save modified or proprietary components for later use. This will reportedly reduce the cost of building and editing a cell by approximately 50%.

Software developers have also added several customer-driven improvements. These improvements support the latest CAD formats, and include enhancements to the CAM modules, user interface and user experience to facilitate the creation of trajectories and further improve programming.

Related Content

-

Tips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

-

ERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.

-

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.