Siemens NX Update Adds Model Based Definition

Siemens’ NX Model Based Definition adds support for non-geometric data within CAD digital twins, adding to their accuracy and utility for the production process.

Share

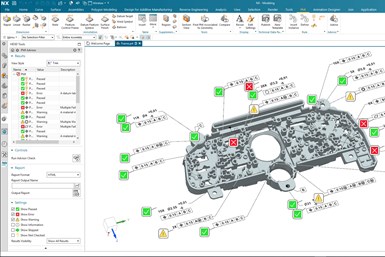

Siemens Digital Industries Software has updated its NX software with a rules and knowledge-based approach to Model Based Definition, which builds in best practices and leverages artificial intelligence to improve productivity. NX Model Based Definition provides data sets that define a variety of characteristics beyond size and shape to improve the comprehensiveness of digital twins. By including non-geometric data within the CAD model, engineers can now produce a complete digital definition of a product in an annotated and organized manner, creating alignment throughout the production process.

Siemens says the patented NX Model Based Definition technology, a first to the industry, solves many challenges companies face when digitalizing the design process and transitioning from 2D to 3D. In trying to replicate a drawing-based workflow in the context of 3D CAD design, many companies end up with a 3D drawing, which does not have the tools to capture the true business intelligence needed to take advantage of the digital twin and digital thread.

Designers and engineers can use NX Model Based Definition to automatically create and reuse data, adding more intelligence to the model, and subsequently leverage the data to inform other products and decisions – moving to a model-based enterprise. Avoiding the manual process of data validation and correction can help enterprises leverage their designs in a new and innovative way, enhancing productivity across the business.

Related Content

-

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.