-

SPONSORED

-

SPONSORED

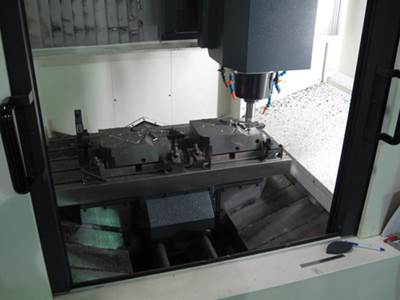

Die/Mold

How to Overcome an Acc/Dec Limitation in High Speed Machining

A small pocket in a graphite workpiece limits productivity. Part of the expert’s response is to consider how a lower feed rate might actually be more productive—because the machine will spend more time at the programmed rate.

Read MoreFinished Molds Overnight

In the highly competitive athletic footwear market, moving from concept to design to production at breathtaking speed is imperative. Fast and efficient five-axis machining is a key accelerator in this process.

WatchVideo: 3+2 Mold Machining at Eifel

A maker of injection molds for high-appearance-quality parts describes the machine tool, software and strategy this shop uses to apply 3+2 machining.

WatchHard Milling Isn’t Just High Speed Machining

Milling complex forms in hardened tool steel involves more than just fast, light cuts, says this maker of medical-related injection molds. Here are some of the ingredients of an effective hard milling process.

WatchAnother Angle On HSM

The savings in setup time were welcome enough, but this mold maker found that a 3+2 machining center also accelerated its use of high speed machining.

Read MoreThe Progress of a Progressive Die Maker

This shop sees no long-term threat in the reality of lower prices. Machine tool investments related to various die components allow the shop to use skilled labor more efficiently.

Read MoreWhen to Mill Keeps Changing

Technology improvements steadily expand the range of tool and die parts that justify high speed machining.

Read MoreVideo: The Role of Heat in High Speed Machining

In high speed machining of die/mold steels, the heat has a more beneficial effect than the role it plays in conventional cuts.

WatchAluminum Molds In Three Weeks Or Less

While aluminum molds are commonly used to create prototypes or to serve as stopgap bridge tooling, they are starting to receive greater attention for production work. This shop’s approach to creating aluminum molds in one day to three weeks is the same for each of these situations.

WatchThe Momentum Behind Aluminum Tooling

A growing number of OEMs are looking to aluminum production molds in order to reduce tooling costs and speed new product time to market. Opportunities exist for shops poised to manufacture such nonferrous tooling.

Read More