-

SPONSORED

-

SPONSORED

Software

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreOpen Mind Technologies CAD/CAM Software Suite Enhances Intelligent Workflow

IMTS 2024: Open Mind Technologies showcases its hyperMill CAD/CAM software with enhancements to its toolpath capabilities, overall functionality and more.

Read MoreMachine Monitoring Spurs Shop's Meteoric Growth

EPTAM Precision Plastics has achieved multiple years of 15% YoY growth by effectively applying Datanomix’s benchmarking and machine monitoring features.

Read MoreNikon Metrology's CT Software Provides AI-Assisted Imaging

Nikon’s AI Reconstruction technology enables rapid results and optimized analysis by applying deep learning techniques to enhance image quality.

Read MoreOpen Mind CAD/CAM Software Increases Programming Efficiency

The HyperMill 2024 CAD/CAM software enables increased NC programming efficiency in applications ranging from 2.5D machining to five-axis milling.

Read MoreThe Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Read MoreOnLogic Control Features Highly Configurable Design

The Tacton series of panel PCs have thousands of configuration options to provide reliable data access and visualization in challenging environments.

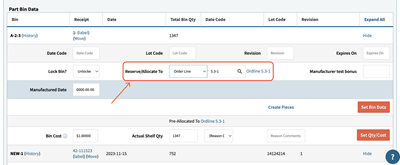

Read MoreCetec ERP System Prevents Slowdowns in Production

The Pre-Allocation feature simplifies the purchasing and material planning process and prevents unnecessary inventory from sitting on the shelf.

Read MoreProtecting Your Automation Investments

Shops need to look at their people, processes and technology to get the most of out their automation systems.

Read More5 Stages of a Closed-Loop CNC Machining Cell

Controlling variability in a closed-loop manufacturing process requires inspection data collected before, during and immediately after machining — and a means to act on that data in real time. Here’s one system that accomplishes this.

Read More