One Auto Parts Supplier's Shift to Ventilators: Now Making 1000s of Parts per Week on Die Delivered in Days

GM applying its supply chain expertise to enable successes such as aiding this ventilator maker to expand sourcing for 700 parts.

Share

Die-Tech & Engineering built and delivered this die for emergency manufacturing of ventilator pistons to Twin City Die Castings within five days of receiving the die caster’s order. Photo: Die-Tech & Engineering.

A recent episode of the NPR podcast “Planet Money” reported on emergency manufacturing efforts to in response to the COVID-19 crisis. The report described how Michigan die maker confronted a die cast part that would typically entail a 12-week lead time, and instead delivered the die fast enough to allow part production to begin within days of receiving the order.

The die went to of Minnesota. The die was for pistons to be used in ventilators by Seattle-area medical device maker .

General Motors (GM) facilitated this. The auto maker partnered with Ventec to multiply ventilator production. Making ventilators needed to remain with Ventec (), but GM was able to aid the company through its power in supply chain management. Ventec ventilators use 700 component from 80 suppliers. The “Planet Money” report describes how GM’s 80-member supply chain team met to extend and accelerate the sourcing of all 700 parts. Twin City Die Castings, whose typical work is largely automotive, is an example of a supplier the auto maker brought in.

Ventec CEO Chris Kiple is quoted regarding a delay with a supplier in India. “GM had people on the ground in India that night” to fix the problem, he said.

Die-Tech & Engineering is the die maker Twin City enlisted for help with the work. The completed die, with cavities for six pistons per shot, was delivered in five days. Twin City is now producing Ventec pistons at the rate of 20,000 per month.

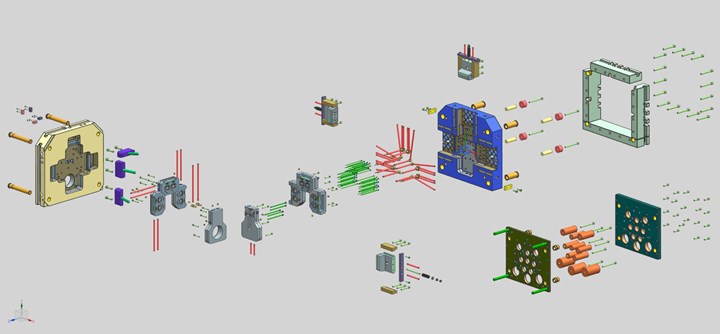

How complicated industrial manufacturing and component sourcing really is. 700 components go into a Ventec ventilator. But this exploded view shows how many components go into the die for making just one of those 700 components. Photo: Die-Tech & Engineering.

Related Content

-

Punch Industry USA Pins, Punches Yield Precision Surface Finishes

PMTS 2025: Punch Industry USA exhibits its “polish-less” custom round and specialized shaped punches, button dies and mold pins.

-

How to Achieve Unmatched Accuracy in Very Large Workpieces

Dynamic Tool Corp. purchases two bridge-style double-column CNCs to increase the cutting envelope and maintain 5-micron cutting accuracy in the long term.

-

Digital Twins Hand Moldmaker a Programming Edge

How can digital twins help solve a labor shortage? This tool and die shop uses digital twin technology to reverse engineer molds for glass bottles, making the process both faster and more reliable.

Related Content

Punch Industry USA Pins, Punches Yield Precision Surface Finishes

PMTS 2025: Punch Industry USA exhibits its “polish-less” custom round and specialized shaped punches, button dies and mold pins.

Read MoreHow to Achieve Unmatched Accuracy in Very Large Workpieces

Dynamic Tool Corp. purchases two bridge-style double-column CNCs to increase the cutting envelope and maintain 5-micron cutting accuracy in the long term.

Read MoreDigital Twins Hand Moldmaker a Programming Edge

How can digital twins help solve a labor shortage? This tool and die shop uses digital twin technology to reverse engineer molds for glass bottles, making the process both faster and more reliable.

Read MoreIn Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.

Read MoreRead Next

Find Your Speed Outside of Machining

This short-lead-time mold shop achieves its most significant time savings by looking outside the machining cycle. However, one of those elements outside the cycle—palletized setup—ultimately led to cycle time savings via five-axis machining.

Read MoreDie Maker Describes Five-Day Build for Tool Urgently Needed for Coronavirus Ventilator Production

Running 11 five-axis machines simultaneously, a die maker reduced a five week lead time to just five days. Here’s how.

Read MoreMachine Shop MBA

Making Chips and Modern Machine Shop are teaming up for a new podcast series called Machine Shop MBA—designed to help manufacturers measure their success against the industry’s best. Through the lens of the Top Shops benchmarking program, the series explores the KPIs that set high-performing shops apart, from machine utilization and first-pass yield to employee engagement and revenue per employee.

Read More