-

SPONSORED

-

SPONSORED

Aerospace

Okuma Supports Aerospace Excellence

The new Aerospace Center of Excellence at Okuma America enables manufacturers to visit, test equipment, confer with experts and learn about CNC machines that are custom-designed for aerospace industry applications.

Read MorePallet System Software Boosts Cell Flexibility

The software running this shop’s newest FMS from Fastems adds a layer of automation that enhances the inherent flexibility, productivity and effectiveness of lights-out operation. Dynamic job scheduling is the key.

Read MorePeople are Part of the Process for Machining Inconel

A Tacoma shop describes its winning strategy for efficient machining of Inconel. That strategy includes careful choices of cutting tools and cutting parameters. It also includes a healthy breakfast.

Read MoreMaking Sure MTConnect Is a Good Fit

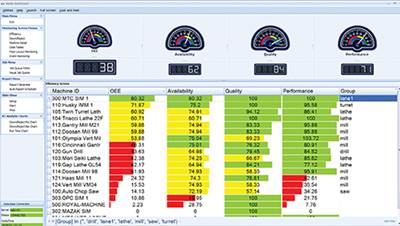

An MTConnect-enabled machine monitoring system gives shopfloor managers information that is driving up utilization rates and improving workforce communication for this manufacturer of high-pressure aerospace fittings.

Read MoreRange of Metal Products Offered

Admiral Metals offers a range of metal products including aluminum, brass, bronze, beryllium, copper, tellurium, stainless steel, centerless ground stainless steel and custom extrusions.

Read MoreWire EDM for Jet Engine “Fir Trees”

Advances in wire EDM (electrical discharge machining) technology have made it acceptable for machining critical aerospace parts. It may now become the preferred method for cutting turbine disc “fir trees,” a particularly demanding application that highlights the benefits of this machining process.

Read MoreCashing in Your Chips

By installing a new chip processing and coolant filtration system, this aerospace manufacturer raised the value of its scrap, slashed new coolant costs and mitigated its environmental impact, shielding itself against potential fluid disposal liabilities.

Read MoreVideo of Interesting Turbine Blade Workholding System

This clamping system is an automated steady rest with measuring capability that stabilizes the five-axis machining process of very long turbine blades.

WatchThe Case for Off-Site Innovation

Okuma says the point of its aerospace technology center is to provide a place for manufacturers to perform all the trial-and-error they need to perfect a new process. It’s also a place to find and consult with sources of up-to-date manufacturing technology expertise.

Read MoreBuild the Machine around the Workpiece

Rather than fitting a part into an existing machine, modular machining units enable building a custom machine particularly suited for that workpiece. This approach is best for large production runs of specialized parts.

Read More