-

SPONSORED

-

SPONSORED

Aerospace

Optimal Milling Strategy For Entering Material From The Side

These animations show why an arc in the same direction as tool rotation is effective. The strategy is relevant for entering material from the edge, as well as for pocketing.

WatchVideo: Finish-Milling Titanium With A 20-Flute End Mill

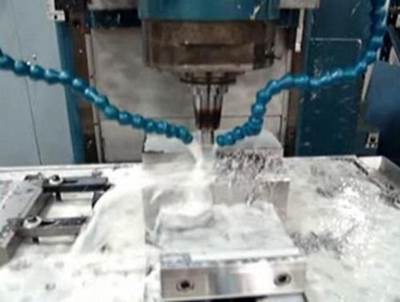

A tool with many flutes can be effective for achieving a productive metal removal rate in titanium, where speed and chip load are constrained. See how quickly the chips accumulate in this video.

WatchSide Turn-Milling Of A Massive Crankshaft

This video footage showing the machining of a massive crankshaft suggests some of the possibilities of turn-milling. Not all shops realize possibilities such as this even on their own smaller-scale turn-mill equipment.

WatchApplication Research For More Efficient Aircraft Machining

A cutting tool supplier describes how application expertise is applied to improving productivity in aircraft-related applications

Read MoreGetting New Business with Big Machines

These shops saved themselves from dependence on the declining automotive sector thanks in part to their commitment to large-scale machining capacity.

Read MoreReplacing Turning with Grinding

This compressor maker’s custom impeller profiles used to present a sticky machining problem. Now, the parts no longer need the wax that turning used to require.

Read MoreThe Anatomy Of An End Mill For Aluminum

By using specialized cutter geometry and incorporating smooth finishes with tough coatings, Toolmex Corp., created an end mill well suited to cut aluminum aggressively. This tool called the "Mako" is part of the SharC line of specialized tools from the same company.

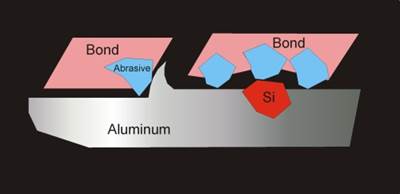

Read MoreNew Honing Options For Hypereutectic Aluminum Cylinder Bores

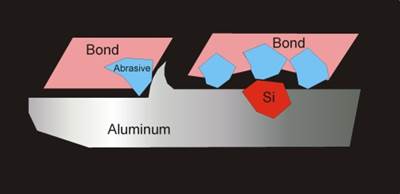

Hypereutectic aluminum is saturated with silicon particles that must be exposed during honing. A two-stage process first hones a cylinder’s wall to a mirror-like finish and then relieves aluminum around the silicon particles.

Read MoreAlternate Tool Material For Hogging Large Workpieces

Shops often use either carbide or high speed steel cutting tools for hogging out the large workpieces common to the aerospace and moldmaking industries. While both materials have their advantages and disadvantages, cutting tool manufacturer Precision Cutting Tools says powder metal combines the best features of both. Â

Read MoreHow to Hone an Atypical Aluminum Alloy

Hypereutectic aluminum used for engine blocks contains silicon particles that must be exposed during cylinder honing. This can be done using a cushioning, elastomer honing tool that allows individual abrasive particles to “bounce” over the silicon particles.Â

Read More