-

SPONSORED

-

SPONSORED

Automation

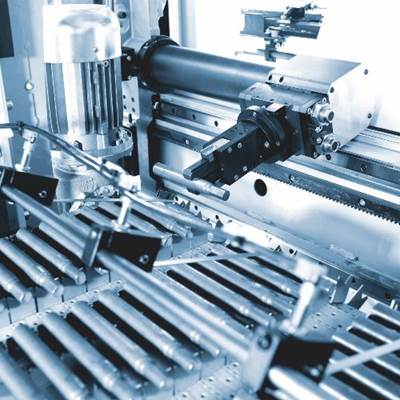

Bar Feeder Enables Faster Changeovers

The Alpha 552 bar feeder from LNS America is designed for fixed headstock machines.

Read MoreThe Basics of Bar Pullers

Bar pullers are cost-effective alternatives to enable automated turning on CNC lathes. Learn how they work and how shops can benefit from using them.

Read MoreCNC Software Update Enables Lights-Out Machining

The Sescoi division of Vero Software will introduce Version 22 of WorkNC.

Read MoreAbrasive Disc Brushes Enable Automation

Brush Research Manufacturing offers its professional-grade NamPower abrasive disc brushes for automated deburring and surface-finish operations.

Read MoreHigh Speed Leads to Lights-Out

This mold maker has become more competitive by establishing a high speed machining process that is predictable enough to confidently run lights-out.

Read MoreSensors Automate Grinding, Dressing Wheel Positioning

By listening for slight changes in sound, acoustic emission sensors enable grinding machine owners to automate their wheel positioning and dressing processes with precision and accuracy.

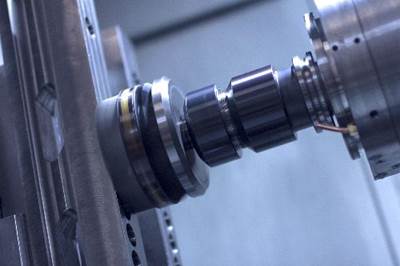

Read MoreBar Puller for CNC Turning Centers

Accudyne’s EZ-Puller bar puller enables semi-automatic operation of CNC turning centers.

Read MoreVF-1: Then and Now

To commemorate its 30-year anniversary, Haas Automation compares the VF-1 machining center of 1988 with the same model today, illustrating how far the technology has come.

Read MoreSpace-Efficient Automation for CNC Lathes

Loader moves entirely within the footprint of the machine.

Read MoreFactory Automation Made Easy

New technology from FANUC offers more than just performance enhancements.

Read More