-

SPONSORED

-

SPONSORED

Automation

Lights out Output

For lights-out machining, being able to efficiently backtrack from smaller batches if something goes wrong helps identify when an error occurred.

Read MoreDo You Have an Automation Strategy?

Contract shop Energy Dynamics said demographics provide one of the reasons why this shop bought a robot.

Read MoreAutomated Fixture Plate Distribution System.

Makino’s MMC-R automation system is designed for robotic fixture plate distribution in HMCs and VMCs.

Read MoreCAM Software Offers Automation Intelligence

Geometric Technologies offers CAMWorks 2010 and DFMPro version 2.1.

Read MoreFixtures Facilitate Transfer Line Automation

Replacing fixtures in an automated transfer line with robot-integrated models from Kurt Manufacturing helped this tier one automotive manufacturer eliminate issues with part distortion and expand production.

Read MoreSpindle Probes Can Automate Trial Machining

An often-overlooked use for spindle probes is in trial machining applications. These applications are useful when a setup person is worried that the cutting tool might not machine a tight-tolerance workpiece attribute correctly on the first try. In this case, an adjustment will be made (commonly using an offset) to ensure that excess material will be left on the attribute.

Read MoreLet’s Go to the (Automation) Video

While visiting shops to gather info and take photos for stories, I and the other MMS editors also look for neat processes that lend themselves to helpful video.

Read MoreNon-Slip Urethane Grippers

The company offers an array of clamps, fixturing accessories and machine tool components suited for OEM, machine, forming and fabricating shops.

Read MoreSoftware Simulates Automation On Stand-Alone Mitsubishi Lasers

DiamondMine automation software, which is designed exclusively for Mitsubishi Laser by Ncell Automation, is said to increase overall efficiency by giving shop owners real-time production feedback on their stand-alone lasers. The software standard provides snapshots of operations and processes in real-time so owners and shop floor operators can monitor and adjust machine performance and proactively remove non-value-added processes.

Read MoreA Significant Cell

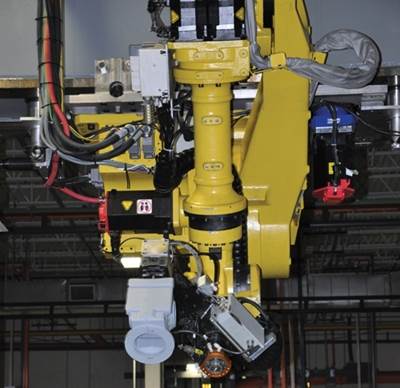

Manual loading of heavy housings was this manufacturer’s prime bottleneck. It had limited experience with automated cells, but decided to install a big one. A look at the manufacturer’s $13 million cell reveals an intriguing layout and blend of technologies.

Watch