-

SPONSORED

-

SPONSORED

CAD/CAM

Beyond Parts from Prints

Domaille Engineering applies design for manufacturability (DFM) principles to both its own product line and the contract work it performs for others. For the latter, DFM enables it to provide customers with much more than accurately machined parts.

Read MoreSoftware Offers Variable Depth Roughing and Other Enhancements

X6 Lathe from Mastercam delivers a suite of enhanced features designed to increase productivity.

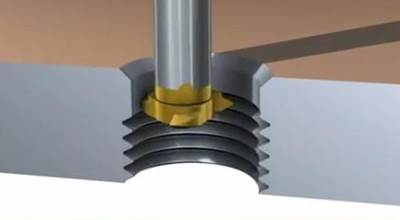

Read MoreThread Milling Explained

Watch this short video from Sandvik Coromant to learn about the advantages of thread milling.

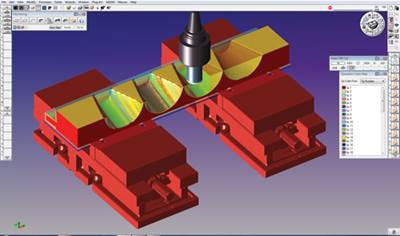

WatchShop Thrives on Evolving CAM Capabilities

High speed, turn-mill and “hybrid” tool paths that combine functionality are among the Mastercam CAM software features that help keep this shop competitive.

Read MoreDirect Interface for Machining Simulation

CGTech and DP Technology have developed the Esprit-to-Vericut interface.

Read MoreNew System Release Offers Direct Modeling, Reverse-Engineering Capabilities

The 2013 release of Delcam’s PowerShape CAD system includes enhancements to its direct-modeling and reverse-engineering capabilities, which are said to make the software more flexible and increase ease of use.

Read MoreEdgecam 2012 R2 CAM Software Supports Advanced Milling

Edgecam 2012 R2 from Vero features a Waveform roughing strategy and Quill support for advanced milling.

Read MorePostprocessing System Eases Technology Adoption

At this aerospace manufacturer, software from ICAM minimizes time spent reworking out-of-the-box postprocessors for new machines and improves confidence in part programs.

WatchCAM Considerations for Plunge Roughing

Plunge roughing is often more complicated than it appears. Here’s how one CAM program addresses some common challenges associated with this technique.

Read MoreCreating Machine-Specific Tool Paths

A new CAM capability takes a snapshot of an individual machine’s performance characteristics and uses the information to tailor an optimized tool path for that specific machine.

Watch