-

SPONSORED

-

SPONSORED

High-Speed Machining

High Speed Machining Without The Fast Spindle

Relying on axial chip thinning lets a larger-diameter tool realize some of the benefits of high speed machining even if the machine's spindle speed is low.

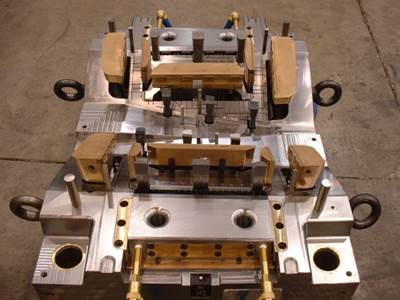

Read MoreFrom Mold Making To Mold Manufacturing

Pro Mold had to change its entire shop culture to make the move to “net machining.” The experience made the company stronger.

Read MoreFor Mold Shops, Machining To Zero Means There Is Nothing To Hold Them Back

Advanced machining technology enables mold shops to produce cores and cavities without leaving extra stock. Following this trend of “machining to zero” will help make mold production more competitive.

Read MoreWhere New Machines And Methods Overshadow The Old

Eclipse Mold makes a good case for high-end machining centers as the basis for effectively machining to zero.

Read MoreCutting To The Model

This mold shop's cutting tool strategies help it eliminate hand spotting altogether by machining complex molds directly to the CAD model.

Read MoreCAM Software Is The Driving Force

Doug Noxell knew he had the right software for machining to zero, so he created a shop to add the rest of the capability.

Read MoreEverything Changes

Through a sweeping transition to high speed machining, a Maryland contract shop realizes its goal of same-day, "in by 9, out by 5" turnaround.

Read MoreCutting Tools For High Speed Milling Of Aluminum

Go with the flow—chip flow, that is. The uninterrupted flow of the soft aluminum chip determines the design of the end mills that Metlfab uses.

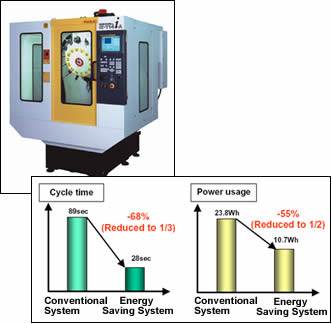

Read MoreCut Faster To Save Energy Cost

High speed machining and other control-related technologies offer real potential for reduced energy costs.

Read MoreThinking Big

This shop specifies large machine tools for the machining possibilities of the future. To prepare for the feed rates the shop expects to use one day, the latest large gantry mills apply linear motors on all three linear axes.

Read More