-

SPONSORED

-

SPONSORED

Machining Centers

Double-Column VMC Accommodates Taller Parts

YMT offers the KMC SR-H/SR series VMC from Kao Ming.

Read MoreDie/Mold VMC Designed for Increased Precision

OKK USA’s VB53 VMC is designed to achieve quality surface finish, high precision and high speed for die/mold applications.

Read MoreMultitasking Machine Combines Versatility and Accuracy

Designed for complex, mid-sized components, the Mazak Integrex i-200ST multitasking machine features a compact design, twin spindles, a lower turret and milling spindle for done-in-one productivity.

Read MoreVMC Developed for Die and Mold Industry

YCM Americas offers the NTV158B, a high-efficiency, T-base VMC for die and mold applications.

Read MoreLarger Equipment Helps Expand Vision

The largest vertical-capacity Carl Zeiss CMM in the Western hemisphere and four large boring mills from MAG Giddings & Lewis prove critical to machining massive wind turbine components at Three-M Tool and Machine.

Read MoreVMC Features Built-In Spindle for High-Speed Cutting

The Hwacheon Sirius UL+ VMC is equipped with a 20,000-rpm, built-in spindle for high-speed cutting.

Read MoreVMC Eliminates Vibration for Micromachining Applications

Makino’s V22 VMC is designed to eliminate vibration, rotational deflection and thermal distortion to ensure precision, accuracy, reliability and stability

Read MoreWhat Your Handbook Isn’t Telling You

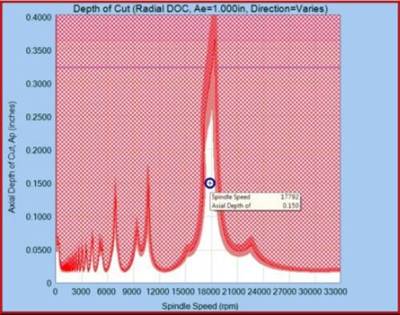

Tony Schmitz, professor at the University of North Carolina at Charlotte, gives a presentation on machine tool dynamics. Learn the role that this concept plays in realizing your optimal machining center performance.

Read MoreVMCs Support Heavy Machining

YMT's QV-179 and 209 VMCs feature a heavily ribbed Meehanite casting for stability.

Read MoreHMCs Offer High-Speed Cutting on Small Footprint

Handtmann offers two sizes of the HBZ CompactCell, the 300/100 and the 200/100, which are suited for aerospace industry applications.

Read More