-

SPONSORED

-

SPONSORED

Machining Centers

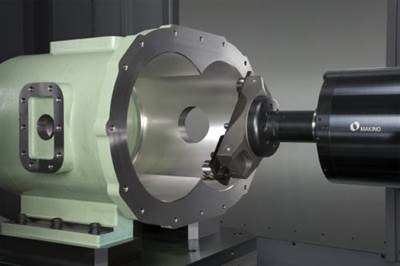

HMC Expands Work Zone

Makino's a81nx horizontal machining center increases the size of the work zone from other NX series machines to accommodate large parts requiring diverse tool types and sizes.

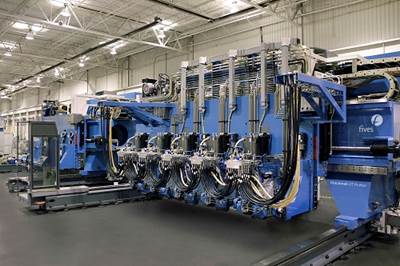

Read MoreProfiler Expected to Exceed 100 Cubic Inches per Minute in Titanium

Five-axis, five-spindle machine aims at reduced cost per piece for production of large aircraft components.

Read MoreA Novel Modular Clamping System

This clamping system minimizes setup times, enable a machine to access five sides of a part and provides highly repeatable positioning for bulky components.

Read MoreFive-Axis Machining Center Features Adjustable Work Envelope

Available from Methods Machine Tools, the Yasda H40i high-precision five-axis machining center is designed for improved repeatability and accuracy, tighter tolerances, and shorter cycle times for aerospace, die/mold and automotive manufacturing.

Read MoreLarge Y-Axis VMC Enables Complete Machining in Single Setup

When Sarro Manufacturing couldn’t manufacture large, aluminum plates in one setup, it installed a Feeler VMP-1100S from Methods Machine Tools Inc. The VMC cut cycle time and spiked productivity.

Read MoreMobile Machining Center Performs Secondary Operations

Southwestern Industries’ Trak 2OP portable machining center streamlines workflow by bringing an additional spindle to an operator for secondary machining operations.

Read MoreHMC Offers Two Spindle Configurations

Kitamura Machinery’s Mycenter-HX500G horizontal machining center provides flexible cutting capabilities for medium to large-sized parts.

Read MoreDrilling and Machining Centers Leverage BTA Process

Unisig’s USC-M series drilling and machining centers combine several processes into one machine capable of drilling and machining all four sides of a workpiece, reducing setup time and increasing accuracy for mold manufacturers.

Read MoreVMC Resists Thermal Deformation

The high-performance NXV1680A vertical machining center from YCM offers extended travels and high rigidity for use in a range of industries.

Read MoreQFS Keeps Its Customers Moving With Integrated CAD/CAM

Quickly updating tool paths to remachine die surfaces enables this shop to provide short runs of prototype formed sheet metal parts. This fast response to engineering changes and design adjustments helps its customers adhere to tightly scheduled vehicle launch programs. QFS relies on integrated CAD and CAM software to make this happen. In this case, the software of choice are PowerShape and PowerMill from Delcam.

Read More