-

SPONSORED

-

SPONSORED

Tooling

Simulation and Tooling Secure High-Value Work

Simulation software and careful attention to tooling parameters have enabled Major Tool to take on ambitious projects with its complex machinery.

Read MoreMate Self-Centering Vises Feature Quick-Change Jaws

Eastec 2023: Mate workholding reduces setup times and process variability, while providing accuracy and repeatability in a compact, quick-change, modular design.

Read MoreJergens' Self-Centering Vise Reduces Jaw Lift

Eastec 2023: The 5CV 130-mm self-centering vise reportedly features clamping forces up to 3,600 lbs.

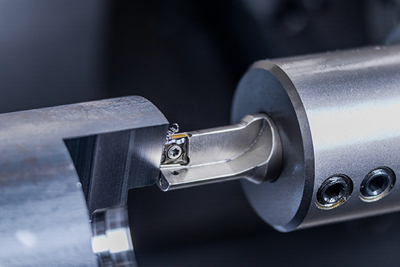

Read MorePalbit Multitasking Tool Provides Flexible Machining

The Multicut tool provides extended tool life, minimizing the need for frequent tool changes and reducing the risk of operator error and tooling issues.

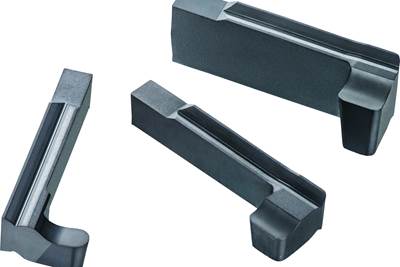

Read MoreSumitomo's Grooving Inserts Bypass Interference

Eastec 2023: The 90-degree inserts are said to be ideal for grooving narrow parts and facing in OD and ID applications that require unique approaches due to interference.

Read MoreSeco Tools' Tapping Tool Lineup Generates Precision Threads

The new line provides three performance levels that enable manufacturers to match the right tap to their particular application.

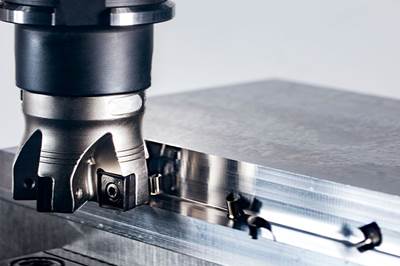

Read MoreCeratizit's Updated Tooling Solutions Improve Machining Performance

The company has upgraded its EcoCut indexable inserts lineup, as well as introduced two new toolholding and workholding solutions.

Read MoreBig Daishowa Chuck Eliminates Chatter in Milling Operations

The Mega 12DS chuck is designed for trochoidal milling with anti-vibration end mills.

Read MoreVektek's Workholding Pump Streamlines Clamping Procedures

Eastec 2023: The Advanced Automation Workholding Pump can be run through a continuously connected rotary union or decoupled pallets.

Read MoreCeratizit's Control System Increases Process Security

Eastec 2023: The ToolScope monitoring and control system can reduce cycle times up to 15% and, with wear monitoring, optimize tool life and provide additional tool reserve usage up to 30%.

Read More