-

SPONSORED

-

SPONSORED

Vertical Machining Centers

VMC Provides High Accuracy

Kitamura’s Mycenter-3XG VMC offers positioning accuracy measuring ±0.000079" and repeatability of ±0.000039". All mounted surfaces requiring assembly are hand scraped to provide full surface contact and proper alignment for long-term reliability, peak performance and accuracy, the company says.The machining center’s thick walls and ribbed box-type, Meehanite-cast construction, coupled with solid box guide ways on the X, Y and Z axes, are designed to ensure quality and rigidity.

Read MoreFive-Axis Machine Blends Power, Small Work Zone

A manufacturer of blisks and impellers needed to quickly find a new five-axis machining center, or risk losing a lucrative job. Two new VMCs fit the shop’s requirements and provided unexpected benefits. (Includes video.)

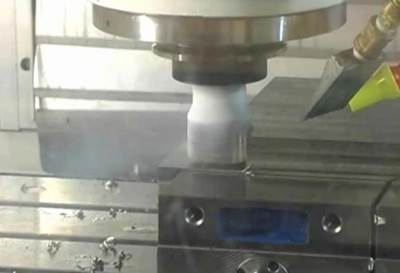

WatchMicromachining Powder Metal on a VMC

By refining its micromachining process for powder metal tool steels, this shop has reduced production costs, lead times and secondary bench work for complex tooling components.

Read MoreVideo: Cryogenic Machining of Titanium

Through-tool liquid nitrogen turns the tool into a heat sink, extending tool life.

WatchVideo: Machining Long Parts Through a Small Machining Center

Video from Chiron America demonstrates the company’s Multi-Profile System, which combines a machining center with in-feed and out-feed accessories so that the compact machine can mill and drill long parts.

WatchPrecise Die/Mold VMC for Roughing and Finishing Operations

With a 12,000-rpm, 20-hp, low-vibration IDD spindle and a structure designed for high damping characteristics, the NDV102A VMC provides high accuracy and reduced vibration, according to manufacturer YCM. The VMC’s 40" × 23.6" × 23.6" X-, Y- and Z-axis travels offer extra working capacity for larger die/mold requirements.

Read MoreMachining Complex Parts on a Five-Axis VMC

Makino’s F5-5XR VMC combines high-performance hard milling with multi-axis capability for increased accuracy, speed, flexibility and productivity.

Read MoreVMCs Feature Pallet Changers

The Quaser MV154 APC, which is a VMC that features 31.4" × 19.6" pallets, includes X-, Y- and Z-axis travels of 27.5", 19.6" and 22", respectively.

Read MoreThe 400° Difference

Cryogenic machining achieves dramatic tool life gains not by flooding the cut, but by refrigerating the tool.

Read MoreFull Model Change for Vertical machining center Series

The NVX5000 series of VMCs from DMG/Mori Seiki has evolved from the NV5000 series as a result of a full model change.

Read More