-

SPONSORED

-

SPONSORED

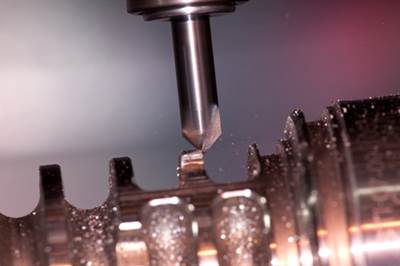

Vertical Machining Centers

High-Capacity, Bed-Type Milling Machine

Knuth Machine Tools’ KB series bed-type milling machines are equipped with large beds and wide columns for handling large parts. The machine design provides increased stability, low vibration and improved precision at high table loads, the company says.

Read MoreBridge Mill Tackles High Speed Net-Shape Machining

The Hi-Net DMC-900HN by Johnford is suited for aerospace manufacturers and mold/die shops that need speed, rigidity and precision in a competitively priced double-column machining center. Absolute Machine Tools, Inc.

Read MoreHow to Improve Machining Center Accuracy

Accuracy is not just inherent to the machine—it also depends on how the machine is used. Try these techniques to let a new or existing CNC machining center achieve its potential precision.

Read MoreTurning On A Machining Center

VIDEO. Part of Renishaw’s automated production process, this turning operation uses tools affixed to the machining center’s table while the workpiece is mounted in the spindle.

WatchVideo: Automatic Part Verification Through Reference Comparison

The machining center in this automated production process inspects its own work and updates its own positioning. Probing a known, traceable reference makes this possible.

WatchCan A Machining Center Be Used As A CMM?

One manufacturer in need of a shop-rugged CMM wants to use a probe-equipped VMC for precisely this purpose. The shop asked probing expert Renishaw about this idea. Here is the response.

Read MoreUsing Small End Mills In Steel Without Breaking

A reader wants to mill with small tools on a straightforward VMC used for full-sized work. MMS Online’s micromachining expert offers advice.

Read MoreLaser Scanning Speeds Holemaking Operations

A laser scanning system offers an alternative to touch probing for quickly finding numerous hole positions in heat-exchanger workpieces.

Read MoreIntegrated Pallet Changer

Designed for high-precision applications in the tool and mold industry, GF AgieCharmilles says its Mikron HSM 300 MoldMaster offers quality surface finishes and high accuracy while also ensuring time-optimized high-speed cutting conditions. The machine includes features and benefits of the company’s GraphiteMaster line, a product consolidation that enables users to choose between MoldMaster (MM) and GraphiteMaster (GM) configurations, increasing flexibility in the job shop.

Read MoreAutomation Cell Maximizes Job Shop Flexibility

Methods Machine Tools’ JobShop Cell is designed for job shops with small to medium lot sizes. The fully integrated production cell combines the drilling, tapping and milling capability of a RoboDrill VMC with a fully interfaced Fanuc six-axis robot for automated loading and unloading.

Read More