-

SPONSORED

-

SPONSORED

-

SPONSORED

-

Workholding

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

WatchShop Doubles Sales with High-Mix, Low-Volume Automation

Robots with adaptive grippers have opened entire shifts of capacity to high-mix, low-volume shop Précinov, doubling its sales.

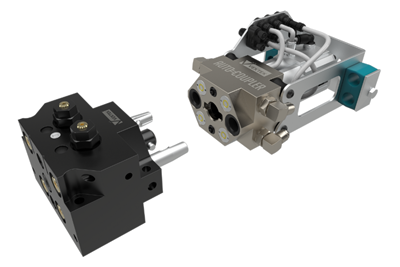

Read MoreVektek Automatic Coupling Device Provides Flexible Fixturing

Westec 2023: Vektek’s Auto-Coupler features two independent air pass-thru circuits and provides the option of part present sensing and part confirmation.

Read MoreParts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

Read MorePascal Engineering Clamp Provides Fast Actuation Speed

The new swing clamp model PLA features a radial, gothic-arch swing mechanism and durable coating ensures that fewer clamp replacements are necessary.

Read MoreDillon Workpiece Stops Reduce Setup Time

The workpiece stops enable short parts to be set above the jaws, providing clearance.

Read MoreKurt Workholding Vises Provide All-Directional Alignment

The DXH Hydraulic vise lineup features the proprietary Kurt AngLock spherical segment to reduce jaw lift and improve performance.

Read MoreFixtureworks Pneumatic Clamp Fasteners Reduce Setup Time

The product lineup includes ball-lock pneumatic fasteners, ID holding, pin holding single- and double-acting pneumatic clamping fasteners.

Read MoreDillon Claw Jaws Provide Increased Holding Power

The company’s claw jaws are designed to bite into the workpiece, enabling more aggressive turning.

Read MorePalmgren Vise Eliminates Jaw Wobble

The bench-and-pipe vise’s spindle and nut are housed in a square tube casting for protection from dust, chips and moisture.

Read More