-

SPONSORED

-

SPONSORED

Aerospace

Training By The Numbers

A formal training program not only helped ease this firm’s transition from cam automatics to CNC lathes, but it also enabled the firm to staff a third shift in record time.

Read MoreSecuring A New Process

A Minnesota manufacturer of precision parts boosts productivity by expanding its workholding capacity.

Read MoreThe Measure Of Success

For this small job shop, measuring and controlling everything are the keys to lean—very lean—manufacturing. Yet its management style is surprisingly open and trusting.

Read MoreUsing The Machine Tool As A Gage

On-machine inspection probing keeps jet engine production flying.

Read MoreSix Advantages Of Horizontal High Speed Machining

Large monolithic aircraft parts may be machined more productively one at a time instead of three at once.

Read MoreWinning The Door Prize

The accuracy of this shop's five-axis gantry-type profiler helped it land the job of machining the engine-bay doors for the F/A-22.

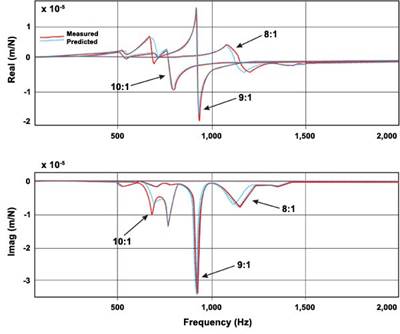

Read MoreThe Overhang Effect

The length by which the tool extends from the toolholder is a variable that can be used to 'tune' the machining process. Contrary to what you may expect, increasing the tool's L:D ratio may reduce chatter and result in more productive milling.

Read MoreHarley Davidson Parts Manufacturer Mills A 'Mile Of Aluminum'

This designer and manufacturer of Harley-Davidson aftermarket motorcycle engines and related components, is using PCD milling to finish engine cases, oil pumps, rocker boxes, inner and outer primary engine covers, and transmission cases and covers.

Read MoreFlexible Grinding, No Grinder Required

At the heart of this process for lean manufacturing of nickel alloy turbine blades are CNC machining centers equipped with grinding wheels.

Read MoreTight Tolerances And Trial Runs

This contract shop is committed to difficult jobs. The shop often takes on a job without knowing how the part will be made.

Read More