-

SPONSORED

-

SPONSORED

Aerospace

Stringer Solution

To reduce cost while improving quality and reproducibility, Airbus UK decided to implement a fully automated process able to machine a stringer complete. The existing production facility was stripped to its steel framework and adapted for the new process.

Read MoreAviation Component Supplier Cuts Setup Time With Productivity Partnership

This shop turned to a tool supplier to help cut milling time on one alloy steel hydraulic body by 63 percent. The success led to a broader Productivity Improvement Program that identified some $87,000 in potential annual savings, and ultimately to a $600,000 payoff by introducing a quick-change modular tooling system.

Read MoreCurvilinear Tool Paths For Pocket Machining

Recognizing the limitations of traditional approaches to pocketing, mathematicians at The Boeing Company have developed a system for generating tool paths that are better suited to pocketing at high feed rates. The same tool paths have demonstrated their usefulness at lower feed rates as well.

Read MoreMaking Profilers More Productive

The trend in aircraft design is larger monolithic aluminum components that are lighter and stiffer than counterparts that are assembled from smaller pieces. Problem is, the larger, more complex parts necessitate significantly longer machining times on conventional horizontal-table profiling machines, underscoring the need for faster, more powerful profiling machines capable of machining a mix of such components quickly and efficiently.

Read MoreNew Contours Of Competition

Toronto aerospace shops improve productivity with faster five-axis machining centers.

Read MoreBoosting Productivity For Turbine Engine Part Makers

Compared with common steel, the heat-resistant super alloys (HRSAs) and other hard metals used in jet engines and ground-based turbines require far longer cycle times per part. Advanced cutting inserts can boost machining throughput with these materials, but achieving these gains requires proper tooling selection and proper implementation.

Read MoreAdvanced CNC Programming Methods Help Manufacturer Meet Tight Deadlines

Nearly every aircraft is prone to tiny cracks that begin at holes used to insert fasteners and that, if not addressed, can eventually migrate from one hole to the next and cause structural failures.

Read MoreEmpowering The Programmer

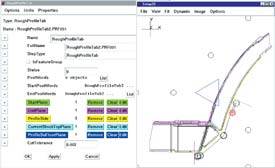

A project aimed at making military aircraft parts faster shows just how much productivity gain can come from automating the programmer's repetitive tasks.

Read MoreStart With Waterjet For More Effective Milling

For aircraft components machined out of plate stock, this shop roughs with abrasive waterjet before finishing with conventional milling. Removing roughing from the machining center cuts cost and lead time.

Read MoreBetter HSM For Big Parts

'High speed machining' is accepted and commonplace in many shops. HSM is so widely used, in fact, that its acceptance is beginning to affect the design of machine tools.

Read More