-

SPONSORED

-

SPONSORED

Automation

GF AgieCharmilles Offers New OSS Smart Machining Feature

GF AgieCharmilles? OSS (Operator Support System) automatically configures cutting parameters to optimize machine performance based on specific job requirements. Standard on any high-speed or high-performance machining center, OSS provides users with an intuitive interface for entering data that is then used to tailor machining processes. When using OSS, operators are asked to rank the relative priority of a job's accuracy, cutting time and surface quality.

Read MoreOkuma Hosts 2nd Interoperability Symposium

The second annual Organization for Machine Automation and Control (OMAC) integration and interoperability symposium is quickly approaching. The event, hosted by Okuma America Corporation, is scheduled for December 3-4 at the Partners In Thinc facility in Charlotte, North Carolina. The keynote speaker is SAP鈥檚 Vivek Bapat, who is also the co-author of 鈥淚n Pursuit of the Perfect Plant.

Read MoreCNC Training Software Uses Actual NC Programs

Siemens Energy & Automation鈥檚 SinuTrain CNC training software is designed to run with Windows XP and is said to be suited for machine tool control-identical simulation training. The software is designed to provide mill and lathe operators with a high degree of practical hands-on experience prior to using the CNCs for the first time, the company says. While using the application, NC programs are developed and simulated using a direct connection to the company鈥檚 CAD systems to further speed the program generation protocol.

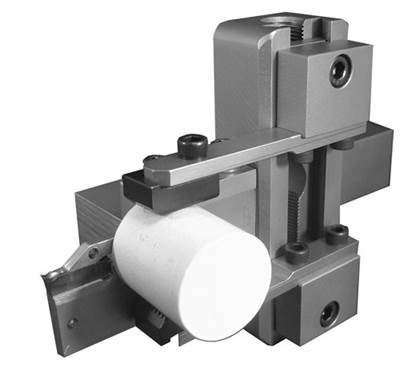

Read MoreAutomation For Chucked Parts

A free-standing parts loading system allows automated material delivery and parts storage so a chucker can run unattended for long stretches of time.

Read MoreOne Tool, Two Turning Functions

A combination bar puller and cutoff tool is an inexpensive way to enable short stretches of unattended turning while saving a turret position.

Read MoreA New Spin On Parts Collection

How do you manage the parts your bar-fed lathe creates overnight? An indexing collection device can serve as an effective means to safely collect precision components.

Read MoreItalian Builders Focus On High-Tech Solutions

More than 96,000 visitors attended the 26th edition of Italy鈥檚 biennial machine tool show, Bi-Mu, from October 3 through 7 at the Fiera Milano exhibition center in Milan. While attendance remained roughly the same as the previous edition, this figure is 鈥渘ot only positive, but also rewarding, considering the particularly turbulent context,鈥� says Giancarlo Losma, president of Ucimu, the Italian machine tools, robots and automation manufacturer鈥檚 association. Many exhibitors say the financial crisis and dollar-Euro exchange rate have had an adverse impact on business in the U.

Read MoreMazak Establishes New Department

聽Mazak Corporation has established Mazak Automation Systems, a new department at its North American headquarters in Florence, Kentucky. The company says the department will offer a comprehensive range of automation solutions and enable customers聽to benefit from聽the company's聽experience in manufacturing and machining technologies. Systems include process and software engineering, project management, application support, customer support and customer training.

Read MoreMachining Center For Lights-Out Production

Incorporating a flexible manufacturing system, the Mycenter-HX400iF HMC from Kitamura Machinery features a 12-station flexible pallet container (FPC) system. According to the company, the center鈥檚 rigid construction; precision; intuitive controls; ability to move easily between difficult materials; and its ability for high speed production make it suited for lights-out production. The company鈥檚 multi-pallet systems enable manufacturers to incorporate an unmanned machining development process for a multitasking machine environment that optimizes up-time.

Read MoreCAD/CAM Software Expands Machining Flexibility

CNC Software鈥檚 Mastercam X3 is designed to increase machining flexibility by emphasizing on speed and automation. With feature-based machining, high speed tool motion and faster toolpath generation, X3 is said to improve shop-floor productivity. The software鈥檚 feature-based machining capability allows automatic milling and drilling of solid models because it can evaluate a part鈥檚 features and automatically develop a machining strategy.

Read More