-

SPONSORED

-

SPONSORED

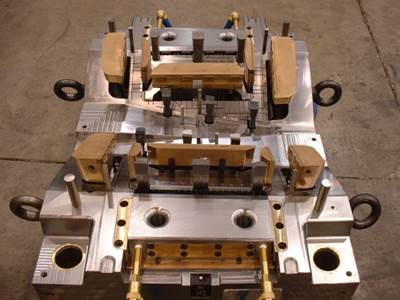

Die/Mold

For Mold Shops, Machining To Zero Means There Is Nothing To Hold Them Back

Advanced machining technology enables mold shops to produce cores and cavities without leaving extra stock. Following this trend of “machining to zero” will help make mold production more competitive.

Read MoreWhere New Machines And Methods Overshadow The Old

Eclipse Mold makes a good case for high-end machining centers as the basis for effectively machining to zero.

Read MoreCutting To The Model

This mold shop's cutting tool strategies help it eliminate hand spotting altogether by machining complex molds directly to the CAD model.

Read MoreCAM Software Is The Driving Force

Doug Noxell knew he had the right software for machining to zero, so he created a shop to add the rest of the capability.

Read MoreHard Milling With Tandem Toolholding

A combination of toolholding choices lets this die shop get the most performance from its small-diameter tools.

Read MoreAn Overview Of 3+2 Machining

An introduction to 3+2 machining: how it works and what it can do for your machine shop.

Read MoreMainstream Technology Keeps Shop On Track

In its toolroom, Branchline Trains takes a practical approach to machining with end mills as small as 0.005 inch in diameter.

Read MoreThinking Big

This shop specifies large machine tools for the machining possibilities of the future. To prepare for the feed rates the shop expects to use one day, the latest large gantry mills apply linear motors on all three linear axes.

Read MoreStrategic Magnetic Workholding

Switching to a modular form of magnetic workholding enabled this global retread supplier to accommodate a greater number of parts in one setup while accelerating cycle times.

Read MoreThe Hard Milling Imperative

Hard milling allows mold components to be machined in the hardened state, thus skipping several expensive and time-consuming processes such as electrical discharge machining and hand polishing.

Read More