-

SPONSORED

-

SPONSORED

Machining Centers

Five-Axis Machine For Dental Applications

Sauer’s Ultrasonic 10 from DMG is a compact, five-axis machine designed for dental indications in soft plastics, demanding metals and high-strength zircon oxide materials.

Read MoreShop Enjoys Five-Axis Benefits Without The Cost

Integrating Lyndex-Nikken rotary tables into three-axis Mori Seiki VMCs provided this shop with five-axis capability at a fraction of the cost of a new five-axis machine.

Read MoreVMCs For Speed, Economy

Doosan’s DNM VMCs are available in three sizes: the DNM 400 with a 36. 2" × 17.

Read MoreThree-Meter Machining Center

Hurco says its largest machining center, the 3-m DCX32, has the capacity to handle large parts and molds for the aerospace and energy sectors. Featuring X-, Y- and Z-axis travels of 126" × 82.

Read MoreTool Certainty

For GKN Aerospace to overcome tool-related variations on its largest milling machines, it had to confront error sources that go unnoticed in many shops.

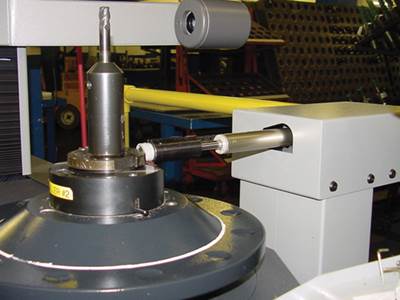

Read MoreHoning On A Horizontal Machining Center

A specially designed tooling package for honing operations, along with live, on-board gaging, allows critical honing operations to move to HMCs, thereby eliminating several separate steps on multiple dedicated machines.Â

Read MoreShifting Gears To Integral Drive Adds Productivity

Machines with geared-head spindles are typically employed for machining titanium and other tough materials that require high torque. However, replacing such models with integral-drive HMCs from Makino has enabled this contract manufacturer to significantly improve productivity on time-sensitive aerospace jobs.

Read MoreAluminum Molds In Three Weeks Or Less

While aluminum molds are commonly used to create prototypes or to serve as stopgap bridge tooling, they are starting to receive greater attention for production work. This shop’s approach to creating aluminum molds in one day to three weeks is the same for each of these situations.

WatchFive-Axis Jig Borer For Die, Mold Manufacturing

Designed for high-precision die and mold machining, Yasda’s YBM-Vi40 five-axis jig borer is said to reduce machining time of complicated shapes in extremely hard materials. The jig borer can tilt the workpiece to reduce cutter length requirements, which enables feed rates of 2,000 mm/min.

Read MoreHMC Designed For Big Parts

Doosan’s HM1250 HMC machines parts measuring 78. 8" in diameter and 67.

Read More